#formwork frame

Explore tagged Tumblr posts

Video

youtube

Four Way Head Manufacturing Video - Wellmade China - Adjustable Fork Hea...

#youtube#four way head#fork head jacks#formwork frame#formwork scaffolding#shoring scaffold#shoring system#wellmade china#wellmade

0 notes

Text

Choosing the Right Formwork Contractor: Key Factors to Consider

When embarking on a construction project, the foundation is key. But what holds that foundation in place during its early stages? Enter formwork—a temporary structure that shapes and supports concrete until it sets. Choosing the right formwork contractor is crucial to ensure your project runs smoothly and stays within budget. With so many options out there, how do you select the best fit for your needs? Let’s explore some essential factors to consider when making this important decision.

Understanding the Importance of Formwork in Construction

Formwork is the backbone of any concrete construction project. It provides the necessary shape and support for the poured concrete, ensuring it sets correctly. Without proper formwork, you risk structural integrity issues. The quality of formwork directly impacts the final outcome. A well-constructed form allows for smooth finishes and precise dimensions, which are vital in achieving architectural designs. Poorly executed formwork can lead to complications down the line, costing time and money. Moreover, effective formwork helps streamline construction timelines. Quick assembly and disassembly keep projects on schedule while minimizing delays. With a reliable contractor at your side, you can expect efficient processes that enhance productivity. Investing in skilled professionals with expertise in formwork pays off significantly. Their knowledge ensures compliance with safety standards while optimizing material use—ultimately contributing to a successful build.

Safety Standards and Compliance

When selecting formwork contractors, safety standards and compliance should be top of mind. Construction sites can be hazardous environments, making adherence to safety regulations crucial. A reputable contractor will prioritize worker safety through comprehensive training programs. They ensure that all team members are well-versed in safe practices and emergency procedures. This not only protects the workforce but also safeguards your project timeline. Moreover, certified formwork contractors utilize equipment that meets or exceeds industry standards. Regular inspections and maintenance of machinery reduce risks significantly. Check if they have a strong track record of compliance with local regulations as well as international best practices. A commitment to following these guidelines reflects their professionalism and reliability on-site, which can ultimately save you time and money during construction projects.

Quality of Materials Used

The choice of materials is crucial when selecting formwork contractors. High-quality materials ensure durability and stability throughout the construction process.

Using inferior materials can lead to structural issues, costly repairs, and delays. It’s essential to ask potential contractors about their sourcing practices for formwork supplies. Look for contractors who prioritize sustainability alongside quality. Eco-friendly options not only mitigate environmental impact but also often offer superior performance. Additionally, inquire about the specific brands or types of materials they use. Trusted names in the industry typically reflect reliability and longevity in construction projects. Don’t hesitate to request examples from previous work. A strong portfolio showcasing diverse applications can provide insight into a contractor's material choices and overall craftsmanship.

For more details, you can visit us:

Reinforced Concrete Foundation

Formwork contractors London

Reinforced Concrete Contractors

#Formwork contractors London#Reinforced Concrete Company#Rc Frame Contractors#Reinforced Concrete Contractors

1 note

·

View note

Text

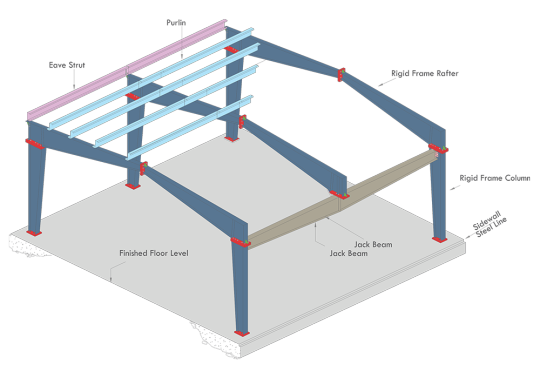

Smith Structure| Jack Beam Elevating Structural Support

Smith Structure introduces jack beams structural component used in construction for temporary or permanent support of floors, roofs, or load-bearing elements

#Jack Beam#Isometric Jack Beam at Sidewall#Isometric Jack Beam at Interior Column Location#Mezzanine System#mezzanine framing system#steel deck support#mezzanine beams#Mezzanine Plan#steel formwork#oncrete slab construction#Mezzanine Cross Section#in#vadodara#Ahmedabad#Kutch#Delhi#Mumbai#Pune#Hyderabad#Indore#Surat#Vadodara#Chennai#gujarat#india

0 notes

Text

Your Partner in Construction Excellence - Choose PAAM Group's Shuttering Plywood!

Looking for reliable shuttering plywood for your construction projects? Look no further! PAAM Group, a trusted name in the industry, presents top-grade shuttering plywood that ensures strength, durability, and unmatched performance.

Why Opt for PAAM Group's Shuttering Plywood?

Proven Expertise: Backed by years of experience in plywood manufacturing.

High-Quality Material: Crafted from premium timber for superior sturdiness.

Custom Solutions: Tailored sizes and specifications to match your needs.

Consistent Performance: Resists warping, bending, and structural deformities.

Cost-Effective: Durable construction saves on replacement and maintenance costs.

Timely Delivery: Reliable supply chain ensures on-time project execution.

Advantages of PAAM Group's Shuttering Plywood:

Smooth Finishing: Provides an impeccable surface finish for your concrete work.

Formwork Stability: Offers excellent stability and support for concrete molding.

Reusability: Designed for multiple usage cycles, ensuring maximum value.

Easy Handling: Lightweight and easy to handle, reducing labor efforts.

Structural Integrity: Maintains structural integrity even under heavy loads.

Weather Resistant: Withstands adverse weather conditions without compromising quality.

Who Can Benefit:

Contractors & Builders: Enhance construction efficiency and structural integrity.

Architects & Engineers: Ensure precision and reliability in concrete work.

Real Estate Developers: Achieve consistent quality in various construction projects.

PAAM Group's Commitment:

Variety: Wide range of sizes and thicknesses available.

Quality Assurance: Stringent quality checks for flawless performance.

Sustainability: Responsible sourcing and eco-friendly production practices.

Customer Support: Responsive assistance for your plywood requirements.

Connect with Us for Premium Shuttering Plywood:

Duration: Year-round availability for all your construction needs.

Contact Us: Visit https://www.paamgroup.com/

or Call + 91 77994 36000 for Inquiries.

Elevate your construction projects with the strength and reliability of PAAM Group's shuttering plywood. Partner with us and build with confidence!

#wood h beams supplier#laminated veneer lumber wood battens#wood h beams manufacturer#wooden h – beams in hyderabad#lumber wood batten manufacturer#film faced shuttering plywood supplier#shuttering plywood manufacturer#plywood formwork panels manufacturer#door frames#film faced plywood

0 notes

Text

Step-by-Step Guide: How to Estimate Construction Costs for a New Home

Accurately estimating construction costs is essential when planning to build your dream home. Understanding and calculating these expenses helps in making informed financial decisions and avoiding unexpected surprises. Here’s a detailed, step-by-step guide on how to perform a thorough construction cost estimate for your new home.

If You Need more Information about cost Estimations, visit this Website -> https://uniqueestimations.com/new-york-construction-estimating-services/

1. Understand the Types of Construction Cost Estimates

There are different methods for estimating costs depending on the stage of your construction project:

Preliminary Estimate: An early-stage estimate based on basic information.

Detailed Estimate: Involves itemized costs for materials, labor, permits, and more.

Bid Estimate: Prepared by contractors and includes detailed pricing for project execution.

Selecting the right construction cost estimator for your project depends on your project’s complexity and accuracy needs.

2. Define the Scope of Your Project

To start estimating, it’s important to clearly outline:

Square Footage: Determine the size of the home.

Design Complexity: Architectural style and special features add complexity and cost.

Quality of Materials: Decide between budget, standard, or high-end finishes.

Having a well-defined project scope ensures that your cost estimation in construction is accurate and reliable.

3. Calculate Material Costs

Material costs often constitute a significant portion of new construction estimating costs. Factors to consider include:

Foundation Materials: Concrete, steel reinforcements, and formwork.

Structural Components: Wood, steel, or concrete framing.

Exterior Finishes: Siding, roofing materials, and insulation.

Interior Finishes: Flooring, drywall, cabinetry, and paint.

Consulting local suppliers and utilizing a construction cost estimator can help you get current pricing.

4. Account for Labor Costs

Labor expenses can vary widely based on your location, the size of your project, and the expertise required. Common roles involved include:

General Contractors: Manage the entire construction project.

Specialized Contractors: Focus on plumbing, electrical work, and HVAC installation.

Skilled Laborers: Carpenters, masons, and roofers.

Make sure to factor in wages, benefits, and potential overtime when estimating construction costs for labor.

5. Include Permits and Legal Fees

Local regulations often require permits for various aspects of home construction, including:

Building permits

Plumbing and electrical permits

Environmental impact assessments

Research the requirements in your area and budget accordingly to avoid delays or fines.

6. Don’t Forget About Utility and Site Preparation Costs

These expenses cover tasks that prepare the land for construction and ensure the home is connected to essential services:

Site Clearing and Excavation: Removing vegetation and leveling the site.

Utility Hookups: Connecting water, sewer, gas, and electricity to the property.

Driveway and Landscaping: Installing access roads and outdoor spaces.

Including these in your construction estimating costs ensures you capture the full scope of expenses.

7. Estimate Plumbing and Electrical Costs

Specialty work like plumbing and electrical installations requires detailed estimates. Utilize a new construction plumbing cost estimator to calculate the expenses for:

Plumbing: Pipes, fittings, and fixtures for kitchens, bathrooms, and outdoor areas.

Electrical Systems: Wiring, outlets, switches, and lighting installations.

These components are critical to home functionality and should be accurately budgeted.

8. Factor in Contingency Costs

Unexpected expenses often arise during construction. To mitigate financial strain, allocate:

5% to 15% of Total Budget: For unanticipated changes or issues.

Price Fluctuations: For materials and labor due to market conditions.

Including a contingency buffer is essential for realistic cost estimation in construction.

9. Use Construction Cost Estimating Tools

Modern technology makes it easier to get accurate estimates with tools such as:

Online Construction Estimators: Provide quick preliminary cost insights.

Software Programs: Offer detailed and customizable reports.

Professional Services: Hiring a professional estimator can add precision and expertise.

Selecting the right tool depends on your project’s complexity and your need for accuracy.

10. Review and Adjust Your Estimate Regularly

As your project progresses, costs may change. Continuously updating your estimate ensures that your budget remains accurate and relevant. Factors to reassess include:

Changes in material prices

Design adjustments

Project delays

Regular reviews help maintain control over your estimating construction costs and prevent budget overruns.

Final Thoughts

Accurately estimating construction costs for a new home requires careful planning, detailed calculations, and regular monitoring. By following these steps, you can confidently manage your budget and make informed decisions throughout the construction process.

If you want to read more information about construction cost Estimation Website just visit --> https://uniqueestimations.com/new-york-construction-estimating-services/

#Unique Estimations#Cost Estimation#construction cost#new home cost#resturants cost#construction labor cost estimator#cost estimation for road construction

2 notes

·

View notes

Text

Modern Building Material Replacements for Longer Life & Sustainability

🧱 Modern Building Material Replacements for Longer Life & Sustainability

The construction industry is evolving rapidly. Gone are the days when cement, bricks, and steel were the only go-to materials. With rising concerns around climate change, cost-efficiency, and structural durability, innovative building material replacements are taking over — offering longer life, lower maintenance, and a more sustainable footprint.

Let’s explore the top modern materials replacing conventional construction elements, and why builders and homeowners in places like Chennai and across India are increasingly opting for them.

🌿 1. AAC Blocks vs. Traditional Red Bricks

Replacement: AAC (Autoclaved Aerated Concrete) Blocks Why:

Lightweight yet strong

Excellent thermal insulation

Faster construction due to larger block size

Resistant to pests, fire, and mold

Cuts down construction time by 30%

💡 AAC blocks reduce dead load on the structure, leading to savings on steel and cement.

⚙️ 2. M-Sand vs. River Sand

Replacement: Manufactured Sand (M-Sand) Why:

Consistent particle size and shape

Readily available and eco-friendly

Reduces overuse of natural river beds

Higher compressive strength of concrete

✅ Many RERA-approved projects now mandate the use of M-sand for structural works.

🧩 3. Precast Concrete vs. On-Site Concrete

Replacement: Precast Concrete Panels and Slabs Why:

Factory-produced for quality control

Rapid assembly on-site

Reduces formwork and labor costs

Fewer delays due to weather

🏗️ Precast is ideal for mass housing, villas, and commercial buildings.

🔩 4. TMT Bars with Corrosion Resistance

Replacement: Fe550D or CRS TMT Bars Why:

Superior ductility and flexibility

Corrosion-resistant properties

Longer lifespan in coastal areas like Chennai

Reduces long-term repair and structural issues

🌊 In saline environments, CRS TMT bars are a must for durability.

🧱 5. GFRG Panels vs. Conventional RCC

Replacement: Glass Fibre Reinforced Gypsum (GFRG) Panels Why:

Faster construction (walls can be erected in days)

Fire-resistant and earthquake-resistant

Excellent for load-bearing structures

Reduces concrete and steel usage

🏘️ Perfect for low-rise and affordable housing projects.

🏠 6. Fly Ash Cement vs. OPC Cement

Replacement: PPC (Portland Pozzolana Cement) Why:

Utilizes industrial waste like fly ash

Enhances durability and water resistance

Reduces heat of hydration — ideal for hot climates

Cost-effective and eco-conscious

🎨 7. UPVC Windows vs. Wooden or Aluminum Frames

Replacement: uPVC (Unplasticized Polyvinyl Chloride) Windows Why:

Resistant to salt, humidity, and rust

No need for painting or polishing

Excellent thermal and sound insulation

Long life with minimal maintenance

🌬️ Especially useful for buildings near the coast or industrial zones.

🚀 Future-Ready Construction Is Here

Investing in these modern material replacements not only reduces your construction cost in the long run but also ensures that your building stands strong against time, weather, and usage. At JRM Construction, we integrate these technologies into our turnkey projects, giving our clients buildings that last longer, cost less to maintain, and perform better across all parameters.

📞 Want to Build Smart and Strong?

Contact us today for custom construction solutions using modern materials:

📍 JRM construction , Chennai 📞 +91-72000 94121 🌐 www.jrmconstruction.in ✉️ [email protected]

#ModernConstruction#SustainableBuilding#JRMConstruction#AACBlocks#SmartBuildingMaterials#BuildStrongChennai#MSand#UPVCWindows#GreenConstruction#IndianBuilders#TumblrArchitecture

0 notes

Text

Centering Panels: The Backbone of Modern Construction with Nova Formworksblr

In the world of construction, precision and efficiency are paramount. One essential component that plays a crucial role in ensuring these qualities is the centering panel. Whether you’re working on a commercial building, a residential project, or infrastructure development, centering panels provide the support and formwork necessary for shaping concrete structures. Nova Formworksblr, a leader in formwork solutions, offers top-quality centering panels that help contractors achieve flawless results every time.

What Are Centering Panels?

Centering panels, also known as formwork panels or shuttering panels, are pre-engineered panels used as molds for concrete structures. They provide a temporary support structure during the pouring and curing of concrete. By maintaining the shape and dimensions of the concrete, centering panels ensure a smooth, consistent finish and structural integrity.

Typically made from materials like plywood, steel, aluminum, or a composite, these panels are designed to withstand heavy loads and resist deformation. The choice of material depends on the project requirements, budget, and frequency of reuse.

Why Centering Panels Matter

Concrete structures must be poured and cured with exact shapes and dimensions to meet engineering specifications. Poorly constructed formwork leads to defects, delays, and costly repairs. Centering panels solve this challenge by:

Maintaining Shape: They hold the concrete in place while it hardens, ensuring the structure takes the intended form.

Providing Strength: Centering panels are strong enough to resist the pressure of wet concrete, even in large pours.

Improving Efficiency: Using ready-made panels reduces the time and labor needed to build traditional timber formwork on-site.

Enhancing Finish Quality: Smooth, reusable panels help achieve a clean concrete surface, reducing the need for additional finishing work.

Ensuring Safety: Proper formwork reduces the risk of structural failures and accidents on construction sites.

Types of Centering Panels Offered by Nova Formworksblr

Nova Formworksblr specializes in delivering durable, high-performance centering panels that cater to a wide range of construction needs. Their product line includes:

Plywood Centering Panels

These panels combine a plywood face with a sturdy frame, offering a cost-effective solution for many projects. Treated plywood panels are resistant to moisture and can be reused multiple times with proper care.

Steel Centering Panels

Steel panels provide exceptional strength and durability, ideal for large-scale and high-pressure pours. Their rigid structure prevents deformation, ensuring precise shapes for demanding projects.

Aluminum Centering Panels

Lightweight yet strong, aluminum panels are perfect when ease of handling is critical. They are corrosion-resistant and have a long service life, making them a favorite for projects requiring frequent assembly and disassembly.

Composite Centering Panels

Combining the benefits of different materials, composite panels offer high strength and excellent surface finish. Nova Formworksblr customizes these panels to fit unique project requirements.

Benefits of Choosing Nova Formworksblr Centering Panels

When it comes to formwork solutions, Nova Formworksblr stands out for its commitment to quality, innovation, and customer service. Here’s why contractors and builders prefer their centering panels:

Superior Build Quality: Nova Formworksblr uses premium materials and advanced manufacturing techniques to produce centering panels that can withstand tough site conditions.

Custom Solutions: Understanding that no two projects are the same, Nova Formworksblr offers custom panel sizes and configurations to meet specific design needs.

Easy Installation: Their panels are designed for quick and secure assembly, reducing labor costs and speeding up construction schedules.

Eco-Friendly Practices: The company emphasizes sustainability by using recyclable materials and promoting the reuse of centering panels.

Reliable Technical Support: Nova Formworksblr provides expert advice and support to help clients select the right panels and maximize their use on-site.

Applications of Centering Panels

Centering panels are versatile and used across many construction sectors, including:

Residential Construction: For building walls, slabs, beams, and columns with consistent quality.

Commercial Buildings: To support large-scale concrete pours with demanding structural specifications.

Infrastructure Projects: Bridges, tunnels, and dams rely heavily on precise formwork to ensure durability and safety.

Industrial Facilities: Factories and warehouses benefit from the robustness of centering panels during foundation and structural work.

Tips for Maximizing the Life of Centering Panels

Proper handling and maintenance of centering panels can greatly extend their service life, reducing overall project costs. Here are some tips from Nova Formworksblr experts:

Clean Panels After Use: Removing concrete residues promptly prevents damage and buildup.

Store Panels Properly: Keep panels in a dry, covered area to avoid exposure to moisture and sunlight.

Inspect Regularly: Check for cracks, warping, or damage before each use and repair or replace panels as needed.

Use Appropriate Release Agents: Applying a release agent prevents concrete from sticking, protecting the panel surface.

Train Workers: Proper installation and dismantling techniques help avoid unnecessary wear and damage.

The Future of Centering Panels with Nova Formworksblr

As the construction industry embraces innovation and sustainability, Nova Formworksblr continues to lead by developing centering panels that meet evolving demands. They are investing in new materials and technologies to create lighter, stronger, and more eco-friendly panels.

Their vision is to support builders in delivering high-quality, safe, and sustainable structures while improving construction efficiency. By partnering with Nova Formworksblr, clients gain access to cutting-edge formwork solutions and expert guidance every step of the way.

Conclusion

Centering panels are an indispensable part of modern concrete construction, enabling precision, efficiency, and quality. Nova Formworksblr offers a comprehensive range of centering panels that cater to diverse project needs while prioritizing durability and ease of use.

Whether you’re a contractor, engineer, or project manager, investing in high-quality centering panels from Nova Formworksblr will ensure your concrete work stands the test of time. Explore their product offerings today and experience the difference professional formwork solutions can make on your next construction project.

0 notes

Text

When disasters strike — whether due to natural calamities or humanitarian crises — the need for fast, functional, and reliable infrastructure becomes urgent. Among the many tools in the disaster response toolkit, wire mesh stands out as a versatile, cost-effective solution for building temporary shelters and supporting critical infrastructure.

From stabilizing structures to securing camps, wire mesh delivers strength, adaptability, and ease of deployment. Here’s how it plays a pivotal role in emergency response efforts:

1. Rapid Construction of Temporary Shelters

One of the first priorities in any disaster relief operation is providing safe and temporary housing for displaced populations. Wire mesh — especially welded and woven types — can be quickly paired with lightweight materials to form:

Structural frames for tents or modular homes

Reinforced wall systems using mesh panels and insulating fabric

Secure window and door coverings

Advantages of wire mesh in shelter construction:

Easy to store and transport in rolls or panels

Fast assembly using minimal tools or technical expertise

Corrosion-resistant — ideal for coastal or humid environments

In emergencies requiring concrete structures (e.g., bunkers or field clinics), wire mesh also serves as reinforcement formwork, strengthening quickly-poured floors and walls.

2. Perimeter Security and Protection of Critical Supplies

In post-disaster environments, security is a top concern. Wire mesh is widely used to create:

Perimeter fences around relief camps

Storage cages for food, medicine, and equipment

Barriers for crowd control and access restriction

These systems are crucial to:

Prevent looting or tampering with aid supplies

Protect vulnerable groups, especially women and children

Establish quarantine or isolation areas when needed

Galvanized or PVC-coated mesh ensures long-term durability in outdoor use, while barbed or razor wire can be deployed in high-security zones.

3. Sanitation and Hygiene Infrastructure

Preventing disease outbreaks is critical in disaster zones. Wire mesh supports the quick setup of:

Temporary toilet and shower enclosures

Waste storage units with natural ventilation

Drainage cages and debris filters for water systems

Its open-grid structure promotes airflow and visibility while maintaining privacy and containment — helping to preserve both public health and personal dignity.

4. Temporary Enclosures for Livestock and Animals

In agricultural regions, disaster-affected families often relocate with their livestock. Wire mesh is ideal for building:

Livestock shelters and holding pens

Barriers to separate animal zones from human habitation

Fencing to protect food stores and crops from animal intrusion

This supports livelihood recovery by preserving essential assets like cattle, goats, and poultry — especially for rural and pastoral communities.

5. Debris Management and Hazardous Zone Control

Disasters often leave behind unstable buildings, sharp debris, and hazardous terrain. Wire mesh contributes to:

Securing dangerous zones or collapsed structures

Stabilizing partially fallen walls or ceilings

Creating walkways, ramps, or makeshift bridges

These applications improve safety for rescue workers and offer reassurance to displaced residents navigating unfamiliar and unstable surroundings.

Choosing the Right Wire Mesh for Emergency Use

Not all mesh is created equal — relief planners should evaluate:

Material Strength: Steel or stainless steel for durability and load-bearing applications

Protective Coating: Galvanized or PVC-coated mesh for weather resistance

Mesh Size and Thickness: Fine mesh for sanitation, thicker gauge for structural support

Ease of Deployment: Pre-fabricated panels or flexible rolls for quick setup

Additionally, wire mesh that complies with international safety and building codes ensures performance and reliability during high-stress deployments.

Partnering with Experts for Rapid Response

At Al Miqat Hardware, we provide high-quality, disaster-ready wire mesh solutions tailored to the demands of emergency environments.

✅ Rapid delivery across the UAE and Gulf ✅ Custom mesh products for specific relief needs ✅ Expert consultation and B2B/B2C technical support

📞 Contact our Disaster Relief Response Team today for bulk orders, custom solutions, or urgent delivery requests.

Conclusion: Strength in Simplicity

In disaster zones, every material must be multifunctional — balancing speed, strength, safety, and flexibility. Wire mesh delivers on all fronts, making it an indispensable tool for emergency shelter, infrastructure, and recovery.

From securing aid stations to building safe living spaces, wire mesh helps communities stabilize, rebuild, and recover. As climate change increases the frequency and intensity of natural disasters, planners and relief agencies must invest in solutions that are not only fast but future-proof.

Wire mesh isn’t just a building material — it’s a building block for resilience.

#wire mesh#sharjah#galvanized wire mesh#stainless steel wire mesh#security fencing#al miqat hardware#oman business#welded wire mesh#wire fencing#galvanized

0 notes

Text

Significance of Aluminum Formwork in Construction Projects | Manufacto India

In the construction industry, significant attention has always centered on the manner of completing projects. Timeliness, accuracy, and budget compliance are critical in achieving these objectives. One of the technological advancements positively shaping this sector is the aluminum formwork system. Owing to its unique properties of strength, reusability, and simplification of the construction processes, aluminum formwork is changing the way developers view modern building projects.

What is Aluminum Formwork?

Aluminum formwork is a rigid system which utilizes high-strength aluminum alloy wherein concrete is poured to form walls, floors, spiral staircases, slabs, etc. Unlike conventional plywood or steel systems, aluminum formwork offers higher precision and repeatability, making it preferable for mass housing as well as high-rise construction.

Construction Benefits of Aluminum Formwork

1. Reducing Time And Improving Efficiency

The use of aluminum space frames speeds up the construction process. As modules, they make the assembly and disassembly easier, reducing overall labor time and improving the timeline of the project.

2. Effective Use of Resources

This advantage alone makes aluminum formwork stand out in the construction industry as it has high reusability rates. A single set can be reused over two hundred times with ease, increasing sustainability and profitability for developers.

3. Exquisite Finish Quality

Because of the aluminum’s precise designs, formworks create smooth, high-quality concrete finishes which eliminates the need for plastering. This precision reduces material costs and labor.

4. Durability and Strength

Aluminum formwork’s repetitive use and rough handling is countered with its strong alloys, aluminum. Its strength ensures a variety of climactic conditions and consistent results.

5. Enhanced Worker Safety

Steel supported structures lower the risk of structural collapse or failure thus improving construction site safety for workload.

Applications of Aluminum Formworks

Residential buildings: used for low-cost and high-volume housing plans where speed and cost control are priorities.

Commercial Projects: Applied in retail complexes and high rise office buildings where precision in construction is critical.

Infrastructure Projects: Used in industrial units, metro stations, and flyovers, which require repetitive construction.

Aluminum Formwork Advantages from Manufacto India

From Manufacto India, we are committed to exceptional real estate project aluminum formwork solutions with unparalleled precision, strength, and functionality. Every system complies with the requirements of the ever-growing Indian real estate and infrastructure market.

Our formwork systems are ideal for township development and for high-rise tower construction, providing precise and faster working.

Final Thoughts

Aluminum formwork goes beyond construction technology; it is a tactical mechanism for improving productivity, quality, and sustainability. Given the urgent need for accelerated urban development, embracing pioneering methods such as aluminum formwork is necessity — not a choice. Contact us

0 notes

Text

Shed Slab Concreting Brisbane: The Foundation of a Long-Lasting Structure

Whether you're building a backyard workshop, rural farm shed, or suburban garden storage unit, one element remains critical across all projects: the slab. A properly laid concrete slab forms the foundation that supports the structure’s weight, handles environmental stress, and maintains level stability for decades. In a region with variable weather and soil conditions like South-East Queensland, the importance of engaging professionals in shed slab concreting Brisbane cannot be overstated.

From site preparation to curing, shed slab concreting demands precision, compliance with local codes, and high-quality materials. Cutting corners here can lead to cracking, subsidence, or even total rebuilds. If you’re serious about a strong start to your shed project, this guide walks you through the process, benefits, and what to look for in a concreting team.

Why Concrete Slabs Are Essential for Shed Builds

The slab is more than just a floor—it’s the structural bedrock that supports everything above it. Especially for sheds designed to house heavy tools, vehicles, or machinery, the concrete must resist load pressures, ground movement, and water ingress. When constructed properly, a shed slab also:

Prevents moisture damage by acting as a barrier between the soil and interior

Improves structural longevity, particularly on sloped or shifting ground

Provides a flat and stable surface for tool placement, shelving, and workspaces

Meets local council requirements for engineering compliance and certification

When engaging experienced contractors such as Shed Slab Concreting Brisbane – Jace Decorative Concreting, you gain peace of mind knowing that your slab is built to last, engineered for performance, and tailored to the shed’s intended use.

Understanding the Shed Slab Process

Shed slab concreting involves several detailed steps, each contributing to the overall durability of the finished product. Here’s what the typical process looks like:

1. Site Preparation The area is cleared, excavated to the required depth, and compacted. This may involve levelling, removal of vegetation, and forming a slight gradient for drainage.

2. Formwork Installation Timber or steel forms are set up to define the slab’s shape and height. These frames must be sturdy and level to prevent concrete leaks or uneven edges.

3. Base Layering and Reinforcement A crushed rock or gravel base provides additional support. Steel mesh or reinforcement bars (reo) are then laid to strengthen the slab and resist cracking from load stress or temperature changes.

4. Concrete Pouring The concrete is poured, vibrated to remove air pockets, and levelled with screeds or power tools. Timing here is crucial to avoid surface inconsistencies or premature setting.

5. Finishing and Curing Surface finishing may include a broom, trowel, or textured finish depending on your needs. Proper curing—keeping the concrete moist over several days—ensures maximum hardness and durability.

For a professional, clean result, Jace Decorative Concreting for professional shed slab concreting brisbane offers full-service solutions, including excavation, reinforcement, pouring, and finishing with expert supervision.

What to Consider When Planning a Shed Slab

Before any concrete is poured, a few key decisions must be made:

Shed Size and Purpose Is it a small garden shed or a large-scale agricultural structure? Load requirements, thickness, and reinforcement will vary.

Access to the Site Can trucks and machinery reach the location easily? Limited access may influence equipment choice and timing.

Drainage and Slope Does the property require drainage planning to prevent pooling or runoff? Slight sloping away from the shed is typically recommended.

Local Council Approvals In Brisbane, most permanent sheds over 10m² require approval and may need engineered slabs that comply with the Building Code of Australia (BCA).

Surface Finish Preferences Will you add flooring later, or do you want a slip-resistant surface for work use? Discuss options like textured, trowelled, or polished finishes with your contractor.

For design ideas and shed layout inspiration, you may browse DIY and project examples at Tumblr’s shed builders showcase or explore the concreting projects feed for community-shared results and slab photos.

Common Pitfalls to Avoid

Even a small mistake in slab installation can have lasting consequences. Here are some missteps to watch out for:

Incorrect slab thickness Going too thin compromises structural strength, especially for vehicle or machinery sheds.

Poor reinforcement Improperly placed or undersized reinforcement may lead to cracking or sagging under weight.

Inadequate curing Allowing concrete to dry too quickly may cause surface shrinkage, reducing long-term durability.

Lack of compaction or drainage Water pooling under the slab or shifting soil can lead to instability or even slab failure.

By partnering with trusted providers of High-quality shed slab concreting brisbane available now, you may avoid costly rework and get a strong start on your structure.

Benefits of Working with a Local Brisbane Concreter

Choosing a local business like Jace Decorative Concreting offers several key advantages:

Familiarity with Brisbane’s soil and weather conditions, ensuring better prep and material selection

Faster response times for quotes, site visits, and aftercare

Compliance with Queensland building codes and council requirements

Custom advice based on your site’s unique conditions and goals

Jace Decorative Concreting has built a strong reputation throughout Brisbane for delivering prompt, clean, and reliable slab work backed by clear communication and long-term durability.

Maintenance and Aftercare

Once your shed slab is complete, maintenance is minimal but important. Here are a few tips:

Avoid heavy loads during the first 7–10 days while the concrete continues curing

Inspect periodically for cracks or shifting, especially if the site is subject to frequent water exposure

Seal the surface if required for oil or chemical resistance, especially in workshop or storage environments

A well-constructed slab should require little upkeep and offer a lifetime of performance when installed correctly.

Final Thoughts

When done right, shed slab concreting Brisbane lays the groundwork for everything to follow—whether it’s a small backyard project or a fully operational workshop. By understanding the process, avoiding shortcuts, and engaging skilled professionals, you set your project up for lasting success.For those ready to build with confidence, Shed Slab Concreting Brisbane – Jace Decorative Concreting provides all the tools, expertise, and support needed to create a solid, enduring foundation for any structure.

0 notes

Video

youtube

Lower Adjustable Components for Formwork Frame Tower System - Wellmade C...

#youtube#scaffold base jack#base jacks#jack base#scaffolding base jack#adjustable base plate#frame saffolding#scaffolding parts#scaffolding components#shoring frames#formwork frames#hi load scaffold#heavy duty scaffold#wellmade scaffold#wellmade china#wellmade

0 notes

Text

Strength and Safety: How Indian Manufacturers Are Reshaping Construction with Hot Rolled Strips

Introduction: Safety is Not a Luxury—It’s a Necessity

In the world of construction, safety is not just a guideline—it is a commitment. Every beam erected, every scaffold installed, and every structure raised carries human lives in its balance. The quality of materials used can be the difference between security and tragedy. Today, responsible and forward-thinking Hot Rolled Strips Manufacturers in India are taking this commitment seriously, reshaping the landscape of Indian construction by prioritizing structural integrity, consistency, and above all, safety.

This shift is not driven by profit margins but by an urgent need to protect the countless lives that depend on durable and dependable construction. Engineers, laborers, site managers, and end-users all rely on the invisible backbone of metal components that hold everything together. These manufacturers understand that their materials aren’t just products—they are lifelines.

Understanding Hot Rolled Strips and Their Crucial Role

What Are Hot Rolled Strips?

Hot rolled strips are steel products processed at high temperatures and then rolled into thin sheets or strips. These strips form the foundational raw material for countless construction components, including scaffolding parts, structural beams, pipelines, and machinery frames. They are valued for their:

High strength and flexibility

Cost-effectiveness in large-scale projects

Ability to be easily shaped and fabricated

Why Quality Matters More Than Ever

In the pursuit of faster and taller buildings, cutting corners on material quality can—and does—lead to accidents. The reality is sobering. Structural collapses, scaffold failures, and pipeline ruptures are too often the result of substandard materials. Responsible Hot Rolled Strips Manufacturers in India are stepping up by investing in:

Advanced rolling mills with precision controls

BIS and ISO-certified processes

Rigorous internal testing for thickness, tensile strength, and fatigue

These efforts ensure that the end materials are not just strong on paper—but dependable under pressure, time, and the unpredictable conditions of a live construction site.

The Human Cost of Compromising Material Integrity

Behind every construction mishap is a human story—an injured worker, a delayed project, a grieving family. It’s easy to lose sight of these truths in boardrooms and budget meetings. But the people at the heart of the manufacturing sector—engineers, metallurgists, and safety officers—see it differently.

For them, every shipment of hot rolled strips carries a moral responsibility. A poorly made strip can compromise an entire structure. This deep empathy for end users, especially those working on the frontlines of construction, is why top-tier Indian manufacturers are taking a more holistic approach. They are no longer just supplying materials—they are partnering in the mission to build a safer nation.

The Growing Role of ERW Square Section Pipes in Modern Infrastructure

Expanding Applications in Safety-Critical Areas

Scaffolding, temporary support structures, guardrails, and formwork systems all rely on a secondary but vital class of steel products: ERW square section pipes. These are formed through Electric Resistance Welding and provide excellent load-bearing capability due to their uniform structure and cross-sectional strength.

Today, trusted ERW Square Section Pipes Manufacturers in India are complementing the work of hot rolled strip producers by delivering piping solutions that are:

Dimensionally consistent and easy to install

Resistant to corrosion and environmental fatigue

Engineered to handle both static and dynamic loads

Together, these components form the frame upon which safe construction stands. A worker climbing a scaffold, a child entering a newly built school, or a technician on a maintenance platform—all unknowingly rely on these systems. That’s why empathy must inform every stage of manufacturing—from raw material to final assembly.

Safety Through Standards: What Responsible Manufacturers Are Doing Differently

It’s Not About Checking Boxes—It’s About Saving Lives

The best manufacturers in the industry are moving beyond mere compliance. Instead of simply meeting required IS or ASTM codes, they are:

Investing in third-party audits for quality verification

Developing in-house safety simulation labs

Offering training and education to project engineers and site managers

They are creating products that are not only code-compliant but life-compliant. Because the end goal isn't to sell steel—it's to prevent preventable accidents.

Collaboration Across Industries

Hot rolled strip producers often work closely with pipe manufacturers, structural engineers, and construction consultants to ensure compatibility and safe application of their materials. This cross-functional dialogue is not just about market synergy—it’s about developing systems of safety, not isolated parts.

Building Responsibly: Sustainability in Manufacturing

Eco-Conscious Materials, Long-Term Value

In addition to safety, sustainability has become a moral and professional obligation. Forward-thinking Indian manufacturers are:

Using recycled steel wherever applicable

Minimizing energy consumption during the rolling process

Reducing wastage through precision-controlled cutting

This results in products that are not only safer but also kinder to the environment. It’s a model where industry growth and environmental stewardship walk hand in hand.

Addressing the Real Challenges in the Indian Construction Ecosystem

Counterfeit and Low-Quality Imports

The Indian market continues to face the challenge of counterfeit or under-specification materials being sold at lower prices. While cheaper in the short run, these materials pose severe long-term risks. Reputed manufacturers are leading advocacy for:

Tighter regulations and better enforcement at ports and distribution centers

Awareness campaigns among contractors and builders about the dangers of non-certified materials

Lack of Awareness Among Smaller Builders

Many small and mid-scale contractors are unaware of the benefits and long-term cost savings of using high-quality steel. Leading manufacturers are launching:

Outreach initiatives

Free safety audits

Training modules for local engineers and site workers

Because education is just as vital as innovation in the mission for safer infrastructure.

The Road Ahead: How Do We Keep Improving?

Investing in Research and Development

Modern Indian manufacturers understand that the materials we use today must evolve to meet the challenges of tomorrow. The industry is actively investing in:

Nanostructured steel for higher strength-to-weight ratios

Coated steel strips and pipes for marine or chemical applications

Data-driven quality control using AI and real-time sensors

Fostering a Culture of Responsibility

Ultimately, the evolution of construction safety in India depends not just on better products—but on better values. Manufacturers, contractors, regulators, and even consumers must come together to uphold a culture where:

Cutting corners is no longer acceptable

Human safety takes precedence over financial shortcuts

Quality is seen as a non-negotiable commitment

Conclusion: We’re Not Just Building Structures—We’re Protecting Lives

As we look around at India’s growing skylines, sprawling highways, and rising townships, we must remember that behind each of these achievements lies a quiet, invisible foundation—materials forged with care, precision, and a deep understanding of their impact.

Hot Rolled Strips Manufacturers in India are at the forefront of this transformation. They are proving that industry success does not have to come at the cost of ethics. They are showing that empathy and engineering can—and must—coexist. With the support of allied sectors like ERW Square Section Pipes Manufacturers in India, this new generation of manufacturers is not just producing steel; they are building the backbone of a safer, stronger, and more compassionate India.

Let us not forget: behind every beam is a worker’s hand, a family’s hope, and a nation’s future. And that’s a responsibility no manufacturer should ever take lightly.

0 notes

Text

Premium Lumber Wood Batten Supplier - PAAM Group Offers Quality and Reliability!

Transform your projects with top-grade lumber wood battens from PAAM Group - your trusted source for superior quality and reliable supply.

Why Choose PAAM Group for Lumber Wood Battens?

• Quality Assurance: We take pride in providing only the finest quality lumber wood battens that meet and exceed industry standards.

• Diverse Selection: Choose from a wide range of wood species, sizes, and finishes to find the perfect battens that match your project's requirements.

• Sustainable Sourcing: Our commitment to sustainability means you can trust that our lumber is responsibly sourced and environmentally friendly.

• Experienced Supplier: With years of experience in the industry, PAAM Group has earned a reputation for excellence and dependability.

• Custom Solutions: We understand that each project is unique. Our team can work with you to create custom lumber solutions that suit your needs.

• Timely Delivery: Count on us for on-time delivery, ensuring that your projects stay on schedule without any delays.

Lumber Wood Battens Offered:

• Hardwood Battens • Softwood Battens • Treated and Untreated Options • Various Lengths and Thicknesses • Specialty Cuts Available And more…

Elevate your construction and woodworking projects with the unparalleled quality of lumber wood battens from PAAM Group.

Ready to enhance your projects? Contact us at +91-40-24615104 / 82 or email us at [email protected] to discuss your requirements or visit our website at https://www.paamgroup.com/

PAAM Group - Your partner in premium lumber supplies for successful projects.

#shuttering plywood manufacturer#wooden h – beams in hyderabad#plywood formwork panels manufacturer#laminated veneer lumber wood battens#lumber wood batten manufacturer#film faced shuttering plywood supplier#wood h beams manufacturer#wood h beams supplier#door frames#film faced plywood

0 notes

Text

1 note

·

View note

Text

The Future of Construction with Plastic Formworks

The construction industry has seen various innovations over the years, but few have had as profound an impact as the development of plastic formworks. While traditional formworks such as wood and metal have been staples in construction projects for decades, plastic formworks are rapidly gaining recognition for their superior performance, environmental benefits, and cost-effectiveness. Companies like Nova Formworksblr are leading the way in providing high-quality plastic formworks that cater to the evolving needs of the construction sector.

What is Plastic Formwork?

Plastic formwork is a type of formwork system that uses durable plastic panels to create molds or frames for concrete during construction. Unlike conventional wooden or steel formworks, plastic formworks are lightweight, reusable, and provide an array of benefits, making them an increasingly popular choice for builders, contractors, and developers.

Plastic formwork systems are typically made from high-density polyethylene (HDPE) or other plastic composites that are engineered to withstand the rigors of construction sites while being easy to handle and transport. These systems are designed to be simple to install and remove, saving time and labor costs during construction.

Advantages of Plastic Formworks

Lightweight and Easy to Handle

One of the most obvious advantages of plastic formworks is their lightweight nature. Traditional formworks such as metal or wood can be cumbersome and require a significant workforce to move and install. In contrast, plastic formworks are much lighter, allowing workers to move, install, and dismantle the system with minimal effort. This can result in faster project timelines and a reduction in labor costs.

Durability and Reusability

Plastic formworks are highly durable and capable of withstanding repeated use. Unlike wood, which can warp, crack, or deteriorate over time, plastic formworks retain their shape and strength throughout their lifespan. This durability translates into a longer lifecycle for the formwork, making it a cost-effective solution in the long run.

Furthermore, plastic formworks can be reused multiple times without losing their structural integrity. This reduces the need for constant replacements, contributing to significant cost savings on materials for construction projects.

Waterproof and Corrosion-Resistant

Plastic formworks are highly resistant to water and corrosion, unlike metal formworks, which are susceptible to rust and degradation in wet conditions. In areas where moisture is prevalent, such as coastal regions or places with high rainfall, plastic formworks offer a distinct advantage. Their resistance to environmental factors ensures the formworks remain in top condition, further extending their life and providing long-term benefits.

Cost-Effectiveness

Although the initial investment in plastic formworks might be slightly higher than traditional wood, the long-term cost savings are significant. Due to their reusability, reduced labor costs, and minimal maintenance, plastic formworks provide an economical solution for construction projects. Moreover, because plastic formworks are lightweight and easy to transport, transportation costs can also be lower compared to heavier materials like steel or concrete.

Environmental Benefits

The construction industry has come under increasing pressure to adopt sustainable practices, and plastic formworks contribute significantly to this goal. Being reusable and recyclable, plastic formworks reduce the amount of waste generated during construction projects. This helps minimize the environmental footprint of a project while also contributing to a circular economy.

Furthermore, plastic formworks are made from recyclable materials, ensuring that the formworks can be repurposed at the end of their lifecycle. This is in stark contrast to wood formworks, which often end up in landfills after their useful life.

How Plastic Formworks Improve Construction Efficiency

Faster Installation

Time is a critical factor in any construction project, and plastic formworks are designed to be quick and easy to install. Their lightweight nature and modular design allow workers to set them up efficiently, reducing construction time. This, in turn, leads to faster project completion and lower labor costs.

Enhanced Quality of Finish

Plastic formworks offer a smooth finish on concrete structures, which can reduce the need for additional finishing work after the concrete sets. The precision and consistency provided by plastic formworks result in high-quality concrete surfaces, reducing the time and effort needed for post-construction finishing.

Versatility in Design

Plastic formwork systems are versatile and can be molded into various shapes and sizes, allowing for greater flexibility in design. Whether constructing residential buildings, commercial structures, or infrastructure projects, plastic formworks can be adapted to meet the specific requirements of each project.

At Nova Formworksblr, the company offers a range of plastic formwork solutions that are tailored to meet the diverse needs of their clients. Their formworks are designed to work in both small and large-scale projects, delivering exceptional results every time.

Applications of Plastic Formworks

Plastic formworks are suitable for a wide range of construction applications, including:

Residential buildings: Plastic formworks are ideal for the construction of walls, columns, and foundations in residential buildings, thanks to their ease of use and cost-effectiveness.

Commercial projects: The durability and quality of finish make plastic formworks a top choice for commercial construction, ensuring a smooth and precise outcome.

Infrastructure projects: Whether for bridges, roads, or other large-scale infrastructure projects, plastic formworks are capable of handling the demanding requirements of such constructions.

Retaining walls and landscaping: Due to their modular nature, plastic formworks can be used for retaining walls and landscaping features, offering flexibility in design.

The Future of Plastic Formworks

As the construction industry continues to innovate and evolve, the demand for more sustainable, cost-effective, and efficient solutions will only grow. Plastic formworks are positioned to be a key player in shaping the future of construction.

With their ability to enhance productivity, reduce costs, and support sustainable building practices, plastic formworks will undoubtedly play an increasingly prominent role in construction projects worldwide. Companies like Nova Formworksblr are at the forefront of this shift, providing state-of-the-art plastic formwork solutions that are revolutionizing the industry.

In conclusion, the adoption of plastic formworks represents a significant step forward in improving the efficiency and sustainability of construction practices. Whether you're a contractor, developer, or architect, investing in plastic formworks can offer long-term benefits that will elevate the quality and cost-effectiveness of your projects. As the industry continues to prioritize eco-friendly and efficient building practices, plastic formworks will remain a crucial component of the modern construction landscape.

0 notes

Text

Shed Base Installation In A Day: Myth or Reality?

Creating a suitable Shed Base is usually one major step forgotten when it comes to setting up a new garden shed. The stability, strength, and life of every shed depend on a level, strong base. Setting a shed base, according to several businesses and do-it-yourselfers, can be completed in only one day. But is this really practical, or is it just a tale to entice anxious homeowners? Let's look more closely and differentiate truth from fiction.

Why A Shed Base Is So Important

Understanding first why a quality shed foundation is important allows one to tackle the schedule. A sound base:

Supports the form and stops it from warping or sagging.

Gives a flat surface to guarantee windows and doors open properly.

Help to shield against moisture, which can destroy by causing rot and decay.

Raises the total life of the shed.

Neglecting this stage or hurrying through it might eventually result in expensive damage or even total shed collapse.

Factors Affecting Time To Install A Shed Base

The reality is that several main factors mostly determine whether you finished a shed foundation in one day:

1.Type Of Base.

The decision impacts the installation timeframe significantly since there are many kinds of shed bases.

Concrete Slabs: Dig out, formwork, mix, pour, level, and curing. Although the pouring and leveling work may be done in a single day, concrete must have time to cure—usually 24–48 hours before any weight may be applied.

Paving Slab :Faster than concrete but still needing laying of a sub-base, which entails digging, precision positioning of every slab.

Plastic Grid Systems: Engineered for speed and simplicity of setup, these can frequently be installed in a couple of hours if foundation already arranged.

Pre-made Timber Bases: can be put together rather fast, especially on level terrain;

2.Ground Conditions

Clearing out the need would conserve quite a lot of time since the ground is level already. Preparation might take many extra hours—or even an entire extra day—if the ground is not level, sloped, or rock-stuffed.

3.Personnel And Tools

Extra assistance and the correct equipment (spirit level, shovel, compactor, wheelbarrow, etc.) can turn a several-day project into a fast one. A project that might take a beginner two days could be completed in hours by a seasoned installer working with a helper.

4. Weather Condition

The process might be totally stopped or postponed by rain, extreme heat, or frigid temperatures. Shed Bases wet ground turns closely hard to work with; extreme heat may cause concrete to dry too quickly, therefore creating fissures.

Timeline In Steps For A One-Day Installation

Given perfect circumstances, a typical one-day installation would appear thus:

8:00 to 10:00 AM: Clean the ground free of debris and grass.

10:00 am – 12:00 PM: Compacted sub-base layer applied, ground leveled.

12:00 noon to 1:00 PM: Food pause (vital to keep energized!).

1:00 PM – 3:00 PM: timber framing, laying paver slabs, or putting in a plastic grid network.

From 3:00 PM to 5:00 PM, the site will be finally level checked, compacted, and cleaned.

Even whether the base is poured by 3:00 p.m., installing a concrete slab might still call for extra drying time.

Tips For A Successful One Day Setup

Plan Early; have everything ready the day before including tools and materials.

Check The Weather Forecast: Pick a dry, moderate day.

Get The Site Ready Soon: If able, clear and approximately level it ahead of time.

Get Help: Two or more people make little work.

Choose Quicker Base Alternatives: Plastic bases and paver slabs cut time over concrete.

Myth Or Reality?

Shed base installation in one day is both a deception and a truth.

Totally possible in one day is a shed base finish if you are well equipped and have a basic system like a plastic grid or paving slabs and are working on flat, dry terrain. Still, if one expects to be totally done in one day, dealing with difficult terrain, a big shed, or selecting a concrete slab (which demands curing time) might result in frustration.

Put simply, with the correct preparations, circumstances, and expectations, it's doable.

Final Thoughts

Don’t underestimate the importance of your shed base. Rushing can lead to long-term problems, so even if it takes an extra day or two, it’s worth investing the time to get it right. Whether you DIY or hire professionals, understanding the process ensures you’ll have a sturdy, lasting foundation for your shed for years to come.

0 notes